| Items |

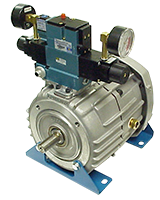

1.5-S 1.5-S Posidyne® Clutch/Brake |

1.5-SA 1.5-SA Posidyne® Clutch/Brake |

1.5-A 1.5-A Posidyne® Clutch/Brake |

1.5-B 1.5-B Posidyne® Clutch/Brake |

1.5-C 1.5-C Posidyne® Clutch/Brake |

|||||

| Description | Today's Posidyne® is a modern motion control device capable of rapid and precise stopping, starting, reversing, speed changing and positioning. The Posidyne® Clutch/Brake being designed to handle the energy of rapid acceleration and deceleration has a field proven history under normal use demonstrating its ability to reduce maintenance normally associated with cycling applications. Use of a Posidyne® also reduces stress on motors and other components in the machine. | |||||||||

| Static Maximum Clutch Torque | 427 lb·in | 387 lb·in | 387 lb·in | 240 lb·in | 427 lb·in | |||||

| Dynamic Maximum Clutch Torque | 367 lb·in | 333 lb·in | 333 lb·in | 206 lb·in | 367 lb·in | |||||

| Maximum Air Pressure Clutch Torque | 60 psi | 70 psi | 70 psi | 70 psi | 60 psi | |||||

| Static Maximum Brake Torque Springs Only | 32 lb·in | 110 lb·in | 110 lb·in | 220 lb·in | ||||||

| Dynamic Maximum Brake Torque Springs Only | 27 lb·in | 95 lb·in | 95 lb·in | 189 lb·in | ||||||

| Static Maximum Brake Torque With Air Assist | 484 lb·in | 492 lb·in | ||||||||

| Dynamic Maximum Brake Torque With Air Assist | 416 lb·in | 423 lb·in | ||||||||

| Maximum Air Pressure Brake Torque | 60 psi | 70 psi | ||||||||

| Maximum Speed | 3600 rpm | |||||||||

| Maximum Kinatic Energy (KE) per Engagement | 11,230 ft·lb | |||||||||

| Basic Cooling Average Thermal | Horizontal 0.25 hp | Horizontal 0.25 hp | Horizontal 0.25 hp | |||||||

| Fan Cooling Average Thermal | Horizotal 0.55 hp | Horizotal 0.55 hp | Horizotal 0.55 hp | |||||||

| Air Volume per Engagement | 0.50 in³ | |||||||||

| Horizontal Oil Capacity | 2.0 | |||||||||

| Vertical Oil Capacity | 2.5 | |||||||||

| Cyclic Inertia | 0.012 lb·ft² | |||||||||

| Typical Applications | Case Packer Catching Roofing Shingles Guillotine Shear Headlamp Inspection Rotary Cut-Off Unscrambler Conveyor | |||||||||

| Features |

Rapid-fire cycle rates of 600 cpm and more capability with the manifold mounted valve. Consistent accuracy with virtually no fade. Ideal in hostile or washdown environments. Nickel-plated shafts and anodized housings available. Low cyclic inertia of only .012 Lb.Ft.2 for ultra-quick acceleration with maximum usable horsepower. Pneumatic actuation for easy control of acceleration/deceleration rates by simply adjusting the air pressure. Smooth and quiet engagements with Oil Shear Technology. Usable with the CLPC-LC™ Closed Loop Positioning Control with an Optical Encoder for optimal positioning accuracy. Easy access C-Face mounting spool design. Fail-Safe |

|||||||||

| Note |

Thermal HP ratings based on 1800 RPM, 80° F ambient, 220° F max.oil temp. Air pressures are at maximum. Operating pressures are generally much lower. Refer to Section 15 “Pressure vs. Static Torque” charts on page 15.7 for proper pressure settings. |

Thermal HP ratings based on 1800 RPM, 80° F ambient, 220° F max.oil temp. Air pressures are at maximum. Operating pressures are generally much lower. Refer to Section 15 “Pressure vs. Static Torque” charts on page 15.7 for proper pressure settings. |

Thermal HP ratings based on 1800 RPM, 80° F ambient, 220° F max.oil temp. Air pressures are at maximum. Operating pressures are generally much lower. Refer to Section 15 “Pressure vs. Static Torque” charts on page 15.7 for proper pressure settings. |

Thermal HP ratings based on 1800 RPM, 80° F ambient, 220° F max.oil temp. Air pressures are at maximum. Operating pressures are generally much lower. Refer to Section 15 “Pressure vs. Static Torque” charts on page 15.7 for proper pressure settings. |

Thermal HP ratings based on 1800 RPM, 80° F ambient, 220° F max.oil temp. Air pressures are at maximum. Operating pressures are generally much lower. Refer to Section 15 “Pressure vs. Static Torque” charts on page 15.7 for proper pressure settings. |

|||||

|

|

||||||||||